The Materials in Extreme Dynamic Environments Collaborative Research Alliance (MEDE CRA) culminated its 10-year program with a virtual capstone event, co-hosted by the U.S. Army Combat Capabilities Development Command Army Research Laboratory (DEVCOM ARL) and Johns Hopkins University. More than 180 people participated in the event, including principal investigators and students from consortium universities, Army researchers and industry partners. Representatives from U.S. Army Futures Command, Office of the Assistant Secretary of the Army for Acquisition, Logistics, and Technology, Office of Naval Research, National Ground Intelligence Center, National Science Foundation, Department of Energy and other DEVCOM subordinate organizations participated as well.

The MEDE CRA is a basic research program led by Johns Hopkins University. The program includes a consortium of 25 university and research partners located in 13 states and three foreign countries. MEDE has developed a materials-by-design strategy, which has resulted in innovative protection materials and computational design codes for armor applications. These new concepts will support the Soldier Lethality and Next Generation Combat Vehicle modernization priorities. According to DEVCOM ARL Dr. Patrick Baker, MEDE successfully achieved its mission by focusing on the three key elements of a basic research program: relevance, team, and science.

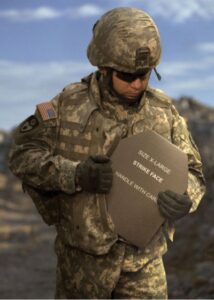

Maj. Gen. Edmond “Miles” Brown, DEVCOM commanding general, highlighted the capstone with a keynote address. He described a multinational force that was attacked while on patrol during a deployment to Afghanistan. The body armor they wore provided the necessary protection to survive the attack and make it back home safely. Additionally, Brown described the evolution of body armor from the time he entered the U.S. Army to present day, and the importance of basic research programs like the MEDE CRA.

Sen. Ben Cardin and Sen. Christopher Van Hollen of Maryland expressed their congratulations to the MEDE CRA. Cardin noted that MEDE has graduated 76 PhD students and transitioned 55 postdoctoral fellows. More than 200 undergraduates participated in research activities; 62 of whom were from HBCUs and minority serving institutions. This highlights the program’s real dedication to inclusivity and diversity, he said. Van Hollen added that MEDE will help save American lives and keep troops safer for years to come.

Officials said a hallmark of the MEDE CRA is its impact on workforce development. Including the university faculty, students, postdoctoral fellows, and DEVCOM ARL researchers, over 600 individuals have been involved in the MEDE research. These individuals include high school and undergraduate student apprentices sponsored through DEVCOM’s Army Educational Outreach Program, and the Army Research Office’s partnered research initiative for HBCUs and minority serving institutions. The MEDE CRA ensured these valuable opportunities were incorporated into the core research program.

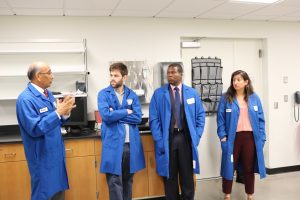

Prof. Lori Graham-Brady of Johns Hopkins and Dr. Sikhanda Satapathy for DEVCOM ARL presented the numerous accomplishments of the MEDE CRA. According to Dr. Satapathy, the goal of the program was to look at the materials or different material classes at different scales, starting from the atomistic scale to the application scale. To achieve this, the MEDE program developed a rigorous mechanism-driven materials-by-design strategy that resulted in new magnesium alloys, boron carbide, and glass-epoxy composites.

In each material, MEDE was able to achieve a weight reduction and improved performance. These discoveries were translated into computational design codes which assisted in validating the experimental data. Industry partners were able to scale-up the laboratory produced materials for ballistic evaluation at DEVCOM ARL.

Graham-Brady said by improving these armor materials they will have a real impact on keeping people safe, which, she said, motivated much of the research.

The capstone included a MEDE CRA video, which provided an overview and successes of the program.

The impact of MEDE to the broader science community will be felt for years, Graham-Brady said. To date, MEDE university personnel and DEVCOM ARL researchers have authored 478 peer-reviewed journal articles. These articles have been cited over 8,000 times. To ensure the legacy of the MEDE CRA, special edition journals featuring MEDE research have been published.

Johns Hopkins University President Ronald Daniels expressed his appreciation to the U.S. Army for sponsoring the MEDE CRA. Johns Hopkins’ partnership with the Department of Defense was seeded in 1940 with the creation of the National Defense Research Committee. MEDE’s innovations will continue to shape the future of the government-university research through the doctoral students and postdocs now working in DOD and national laboratories, academia and global industry.