History of CMEDE

In 2010, two National Research Council boards established a committee to examine opportunities in protection materials science and technology for future Army applications. This committee recommended that the Department of Defense establish an initiative for protection materials by design. This initiative would include a combination of computational, experimental, and materials testing, characterization, and processing research to be conducted by academia, government, and industry.

In response to the committee’s recommendation, in April 2012 the Army Research Laboratory (ARL) established a framework to integrate the Army’s multiscale basic research in materials into one coordinated enterprise. Called the Enterprise for Multiscale Research of Materials (EMRM), the focus of the program is to develop a materials-by-design capability for the U.S. Army using validated multiscale and multidisciplinary modeling capabilities to predict material structure, properties, and performance.

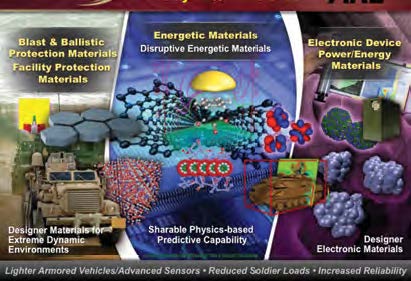

The Enterprise enables ARL to coordinate its in-house activities with extramural research efforts. The EMRM is organized into four major areas: protection materials, energetic materials, electronic materials, and cross-cutting computational science.

To launch the protection materials research component of EMRM, ARL competitively awarded and then signed the Materials in Extreme Dynamic Environments cooperative research agreement with Johns Hopkins University (JHU), the California Institute of Technology (Caltech), the University of Delaware (Delaware) and Rutgers University. The agreement allowed JHU, which is the lead research organization within the consortium of university and research partners, to establish the Center for Materials in Extreme Dynamic Environments, or CMEDE. CMEDE is a center within the Hopkins Extreme Materials Institute, and focuses on

advancing the fundamental understanding of materials in high-stress and high-strain-rate regimes, with the goal of developing a materials-by-design capability for these extreme environments. This 10-year agreement, valued up to $90 million, represents a significant investment and demonstrates the importance of the design of protection materials to the U.S. Army.

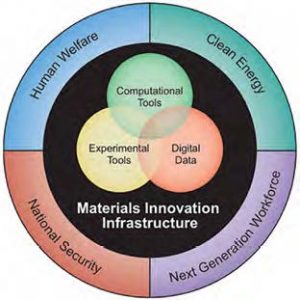

The MEDE program also supports the Presidential Materials Genome Initiative (MGI) for Global Competitiveness. Established in June 2011, MGI aims to double the speed at which materials are discovered, developed, and deployed. The MEDE program represents one of the Department of Defense’s largest investments in extramural basic research in support of the MGI.

National Research Council Report

U.S. Army illustration depicting the EMRM.

Materials Genome Initiative diagram. MEDE focuses on developing the experimental and computationsl tools needed to develop protection materials for national security.