HSP – High-throughput Synthesis and Processing

HT-MAX hypothesis: Novel ultra-high temperature ceramics (UHTCs) with relevant microstructure, geometry, and size will be systematically realized through innovative feedback fabrication and extrusion-based additive manufacturing (AM).

HSP Objectives

- Develop synthesis techniques to enable multi-material coupons for HT characterization;

- Control microstructure via guided printing of the PSD; and

- Understand the kinetic pathways to form novel compositionally complex UHTC powders from methane and ammonia decomposition reactions on a diverse range of refractory alloy powder precursors.

- Study the processing-structure-property relationships via AM approaches with multi-particle inputs to affect microstructure

Synthesis of Compositionally Complex UHTCs

- Gas atomization of custom refractory alloy powders

- Conversion of metallic powders to UHTCs in methane and ammonia

- Alloy composition impact on transformation

- Gas composition impact on competition to form carbides, nitrides, or carbonitrides

- Synthesis and infiltration of porous ceramics to create composites

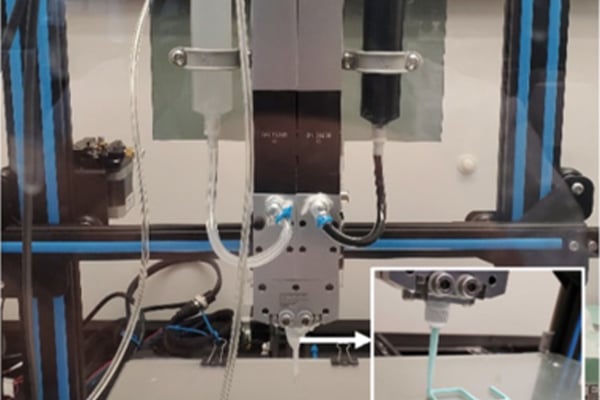

Additive Manufacturing of UHTCs via Material Extrusion

- Utilize novel particle compositions from McCue group

- Investigate dynamic control of discrete and gradient composition

- Control Particle Size Distributions for effect on microstructural development and mixing

- Targeted on-site characterization for faster iterations of throughput

- High-throughput samples for partners