HEMI researchers have access to some of the most high-tech and specialized equipment available in the industry. Below is a sampling of some of the facilities available to our partners and researchers:

For more information or specifics on any of the facilities or equipment available to HEMI constituents, please contact Matt Shaeffer.

Click here to review pricing structures for available pieces of equipment.

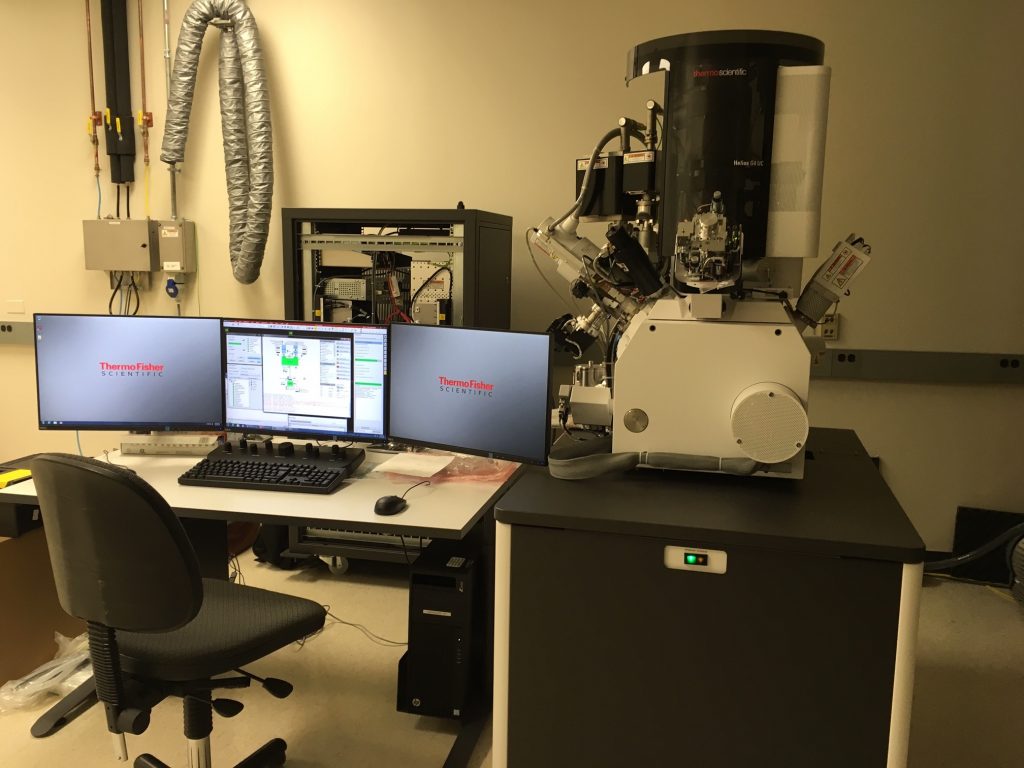

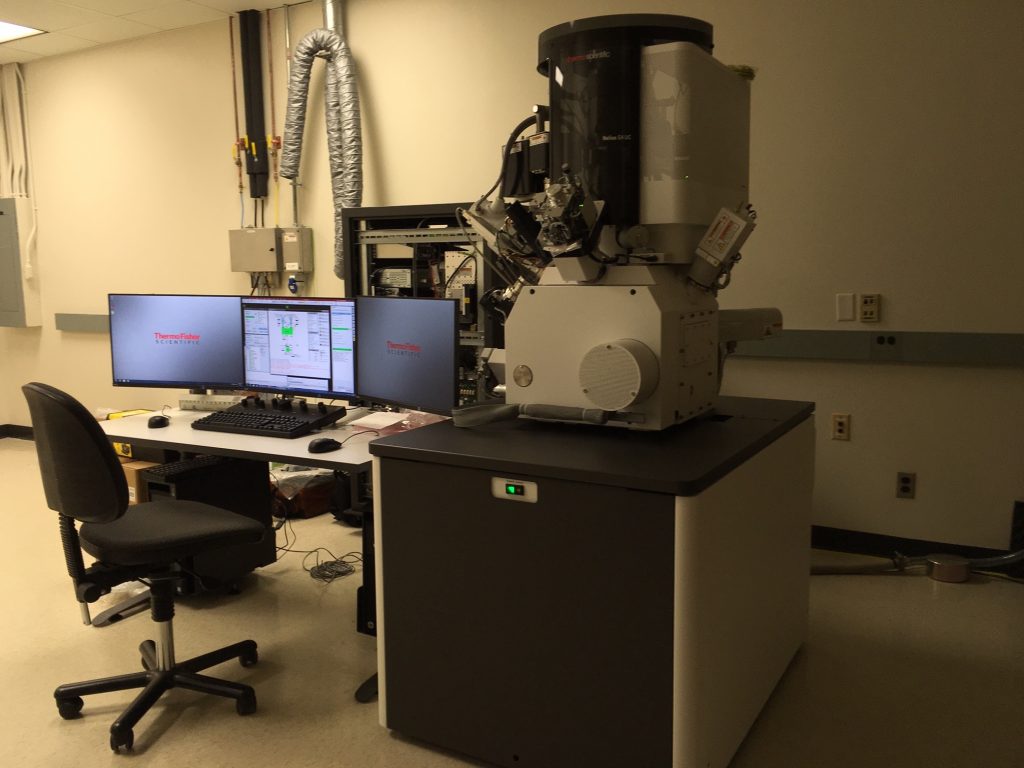

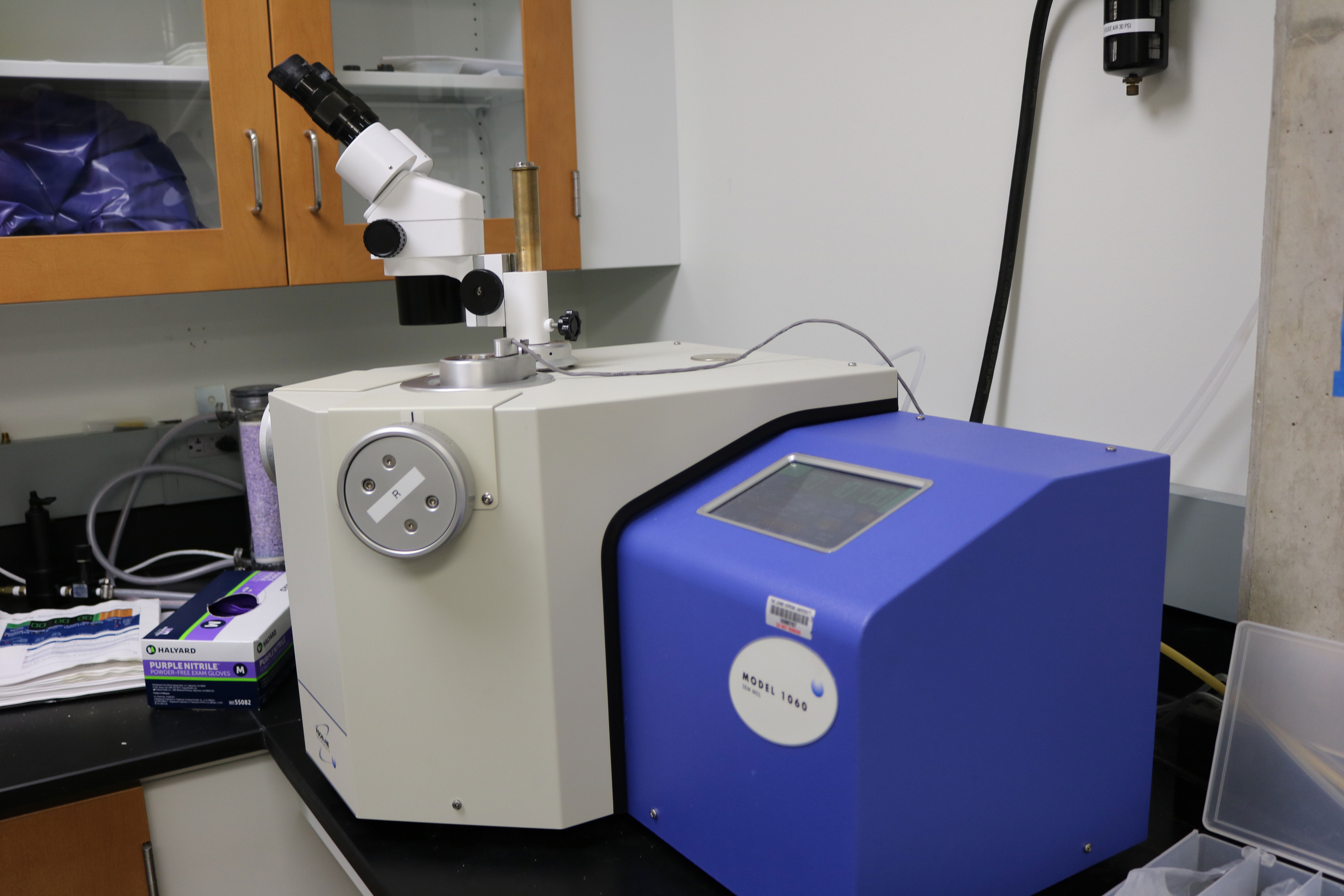

| Focused Ion Beam Facility The Thermo Scientific Helios G4 UC FIBSEM is a cutting edge tool funded by the Whiting School of Engineering, HEMI and the Krieger School of Arts and Sciences and is maintained by the Materials Characterization and Processing Center. This ion and electron beam tool is designed for characterization and fabrication of a wide variety of materials–from biological to metallic. The ion column uses a liquid gallium source to accelerate Ga ions towards samples. This beam can image, then cut the sample, or deposit platinum with extreme precision. The Helios will be used to produce high-resolution secondary and backscattered images, collect 3-dimensional data sets through slice-and-view acquisition, and generate 2D and 3D X-ray (EDX) and crystal orientation maps (EBSD). Three-D volumes are generated on the tens of micrometer scale, which compliments the FS-Laser system. Devices can be fabricated through milling and deposition with nanometer accuracy. The Helios is also designed to produce high-quality TEM grids through a highly automated process or create micro or nanometer test specimens for materials properties experiments. |

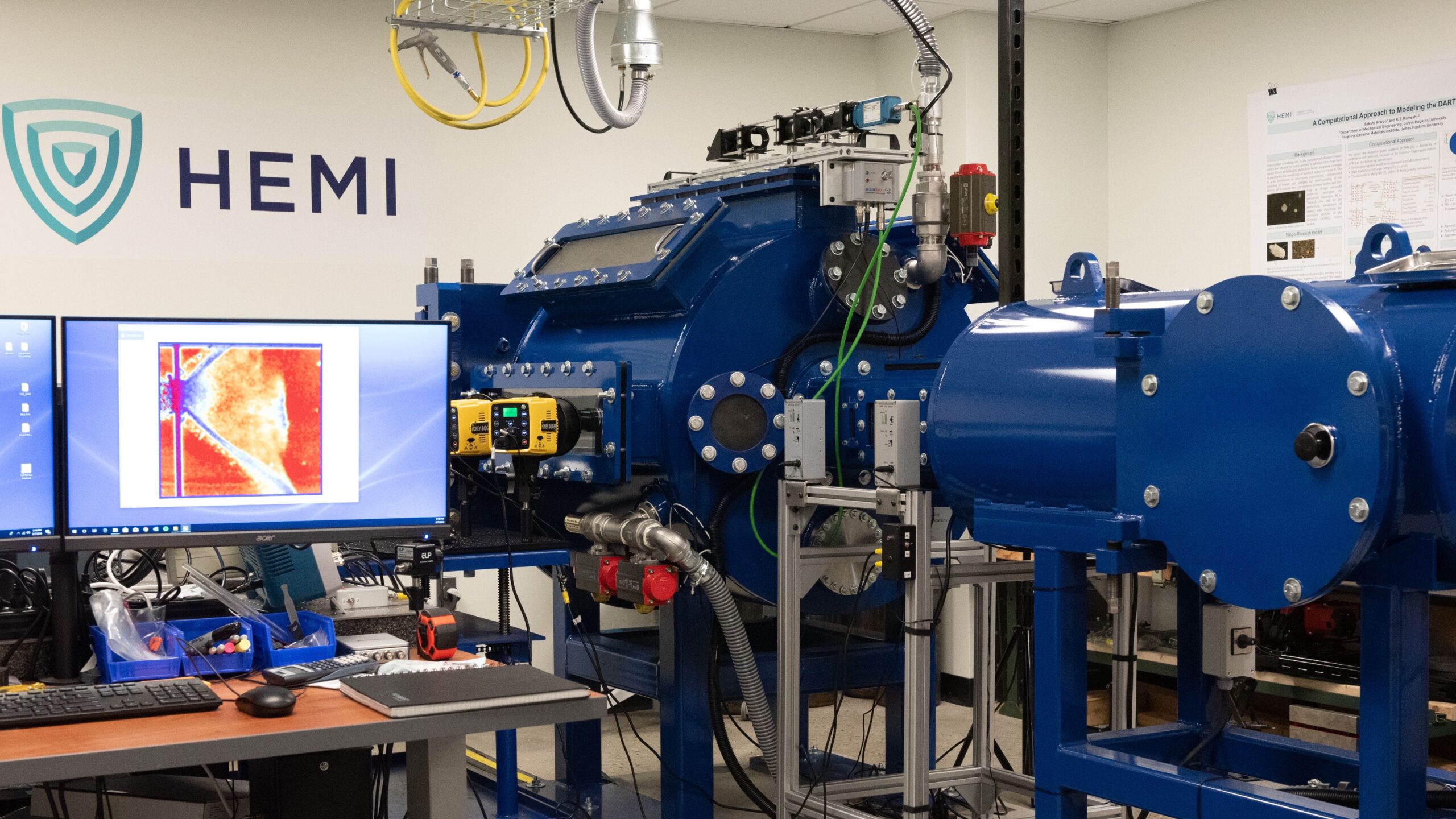

| Hypervelocity Facility for Impact Research Experiments (HyFIRE) The HEMI Hypervelocity Facility for Impact Research Experiments (HyFIRE) contains a 2 stage light gas gun that is capable of launching impactors at velocities up to 7 km/s. The gas gun has a 7.6 mm bore and uses helium or hydrogen, together with saboted projectiles. Typical impactors are spheres or cylinders a few mm in diameter. The facility is not designed to be a high-throughput impact facility, but rather it is designed to perform a small number of experiments with very rich diagnostics and deep datasets. The emphasis is on the coupling of mechanics, physics and chemistry at very high pressures, strain rates and temperatures. The diagnostic facilities includes two flash X-ray tubes, PDVs, other laser interferometers, a Shimadzu HPV X2 high speed camera, and a PI spectrograph.

|

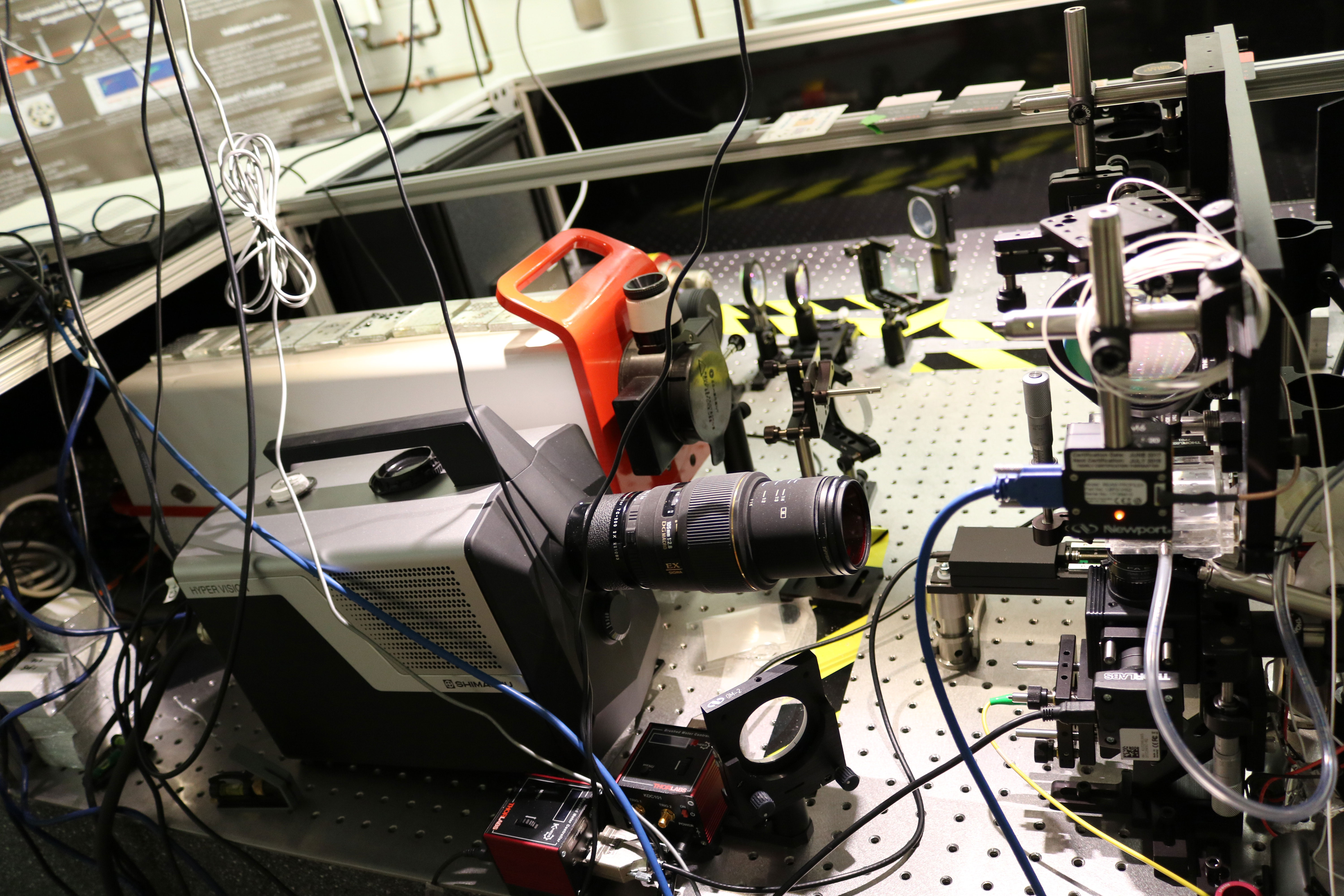

| Laser Shock Facility This facility has a University-scale laser shock capability that can achieve high pressures and ultra-high strain rates for relatively short times. The facility is driven by a Quanta-Ray Pro-350 2.5J 1064nm pulse laser with a 10 ns pulse duration, has diagnostic lasers (an NKT Koheras Basik 45 mW 1550.28 nm CW fiber laser and a Keopsys Erbium Doped fiber amplifier) for photon doppler velocimetry (PDV), a Teledyne Lecroy 813ZI-B 13 GHz oscilloscope, a Coherent Energy-Max-USB/RS pyroelectric energy meter, a Newport Spiricon LBP2-VIS2 Laser Beam Profiler, multiple power meters, signal generator and other equipment. The facility can be used to study the equation of state, to evaluate spall and other high-rate damage processes, and to interrogate laser-matter interactions. |

| Plate Impact Facility The plate impact facility is comprised of a single-stage gas gun with target chamber, laser interferometers, and high-speed data acquisition. The gas gun uses a Duvall-style breech, and launches projectiles at velocities up to 300 m/s, while the gun barrel is 50 mm in diameter and is keyed to allow for oblique (pressure-shear) impact. Normal plate impact and pressure-shear plate impact experiments at velocities up to 300 m/s and strain rates up to 106 1/s can be achieved. |

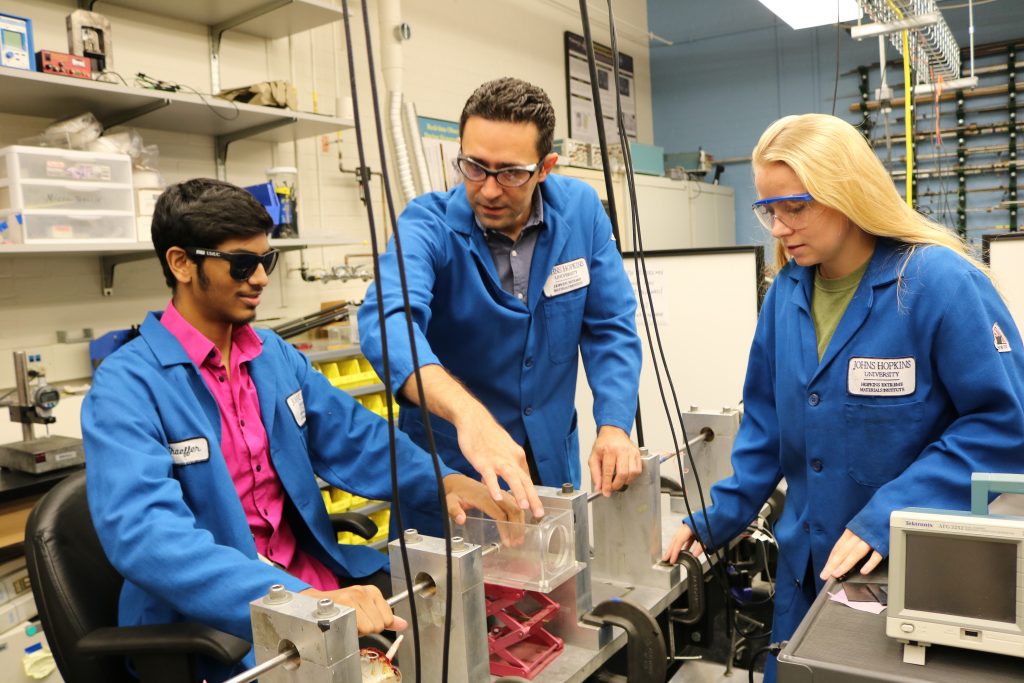

| Kolsky Bar Facility The Kolsky bar facility is a rich-diagnostic high-strain-rate laboratory that is capable of testing materials in uniaxial or biaxial confined stress states at strain rates of 102 to 104 1/s over a range of temperatures (up to 800 degrees Celsius). Equipment includes a conventional compression Kolsky Bar, a Desktop Compression Bar, a torsional Kolsky bar, and a multiaxial bar for tension and torsion. The facilities are able to investigate metals, ceramics, polymers, composites and biological tissues. The instrumentation includes high-speed 12-bit data acquisition systems (LeCroy HDO4034, 350 MHz bandwidth, and 2.5 GHz maximum sampling frequency), laser interferometers, high-speed pyrometry, high-intensity light sources, and several high-speed oscilloscopes. High-speed imaging allows in-situ visualization during testing. A Coherent Sapphire (150 mW, 532 nm) green laser is used for interferometric applications. Recovery capabilities allow us to use SEM, TEM and HRTEM to understand microscopic deformation and failure mechanisms.

|

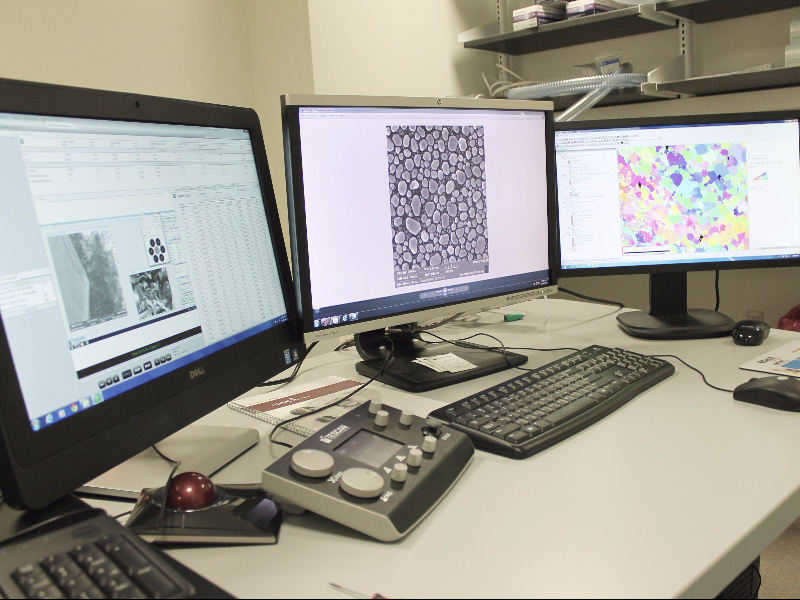

| 3D Characterization Facility This facility contains a Tescan Mira 3 GMU field emission gun SEM with EDAX, Hikari XP EBSD, Octane Plus silicon drift EDS detectors and an in-situ nanoindenter stage. The facility has serial sectioning and imaging capabilities, making use of in-situ surface milling from a femtosecond laser. The femtosecond laser can also be used for micromachining. This Tescan SEM has also been optimized for in situ studies of mechanical behavior (using a Nanomechanics InSEM microprobe for tension, compression, and nanoindentation). A broad ion mill is available. Combining fs-laser milling with broad ion milling and various characterization techniques (e.g. SEM imaging, EBSD, EDS) allows for state-of-the-art collection of 3D microstructural datasets.

|

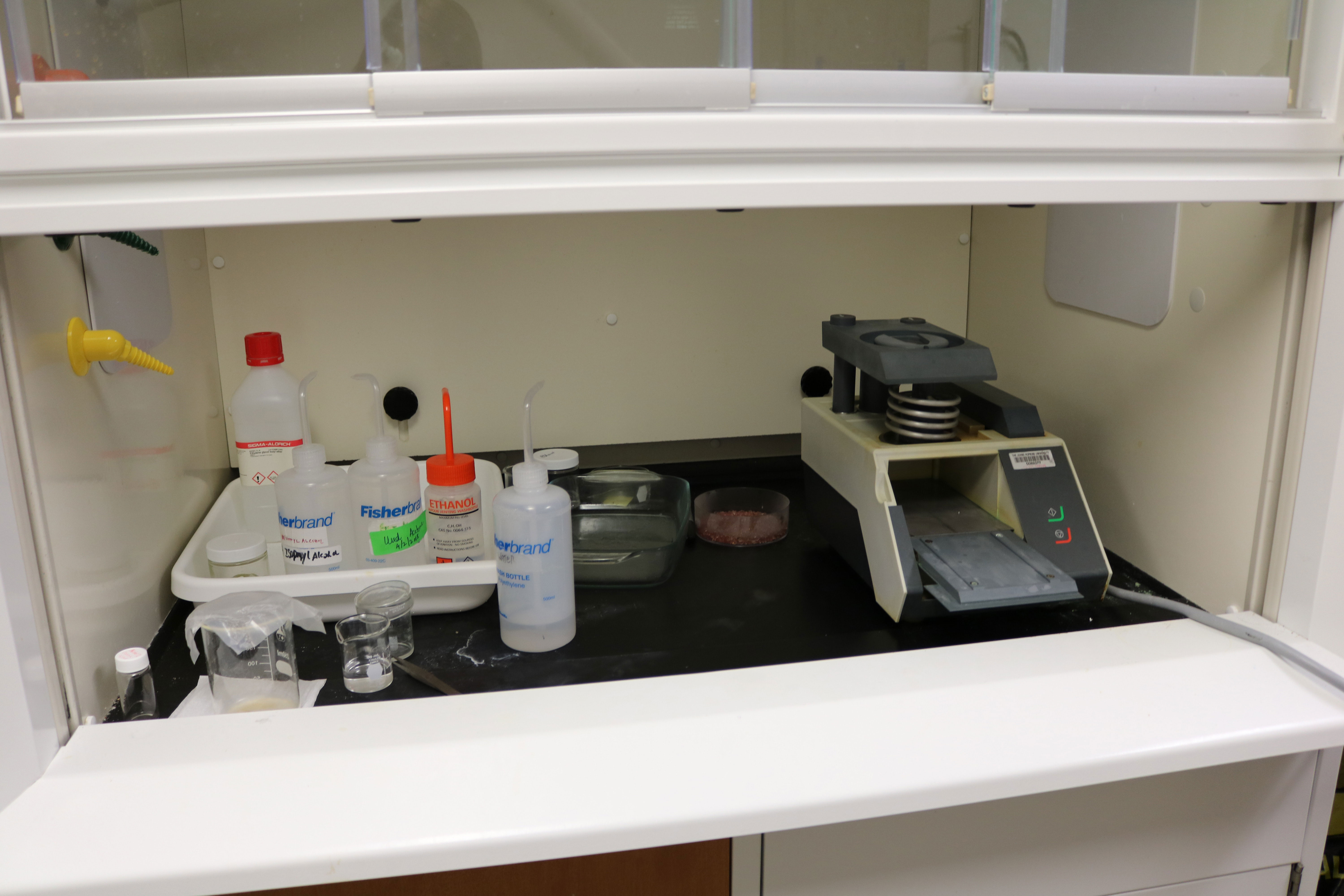

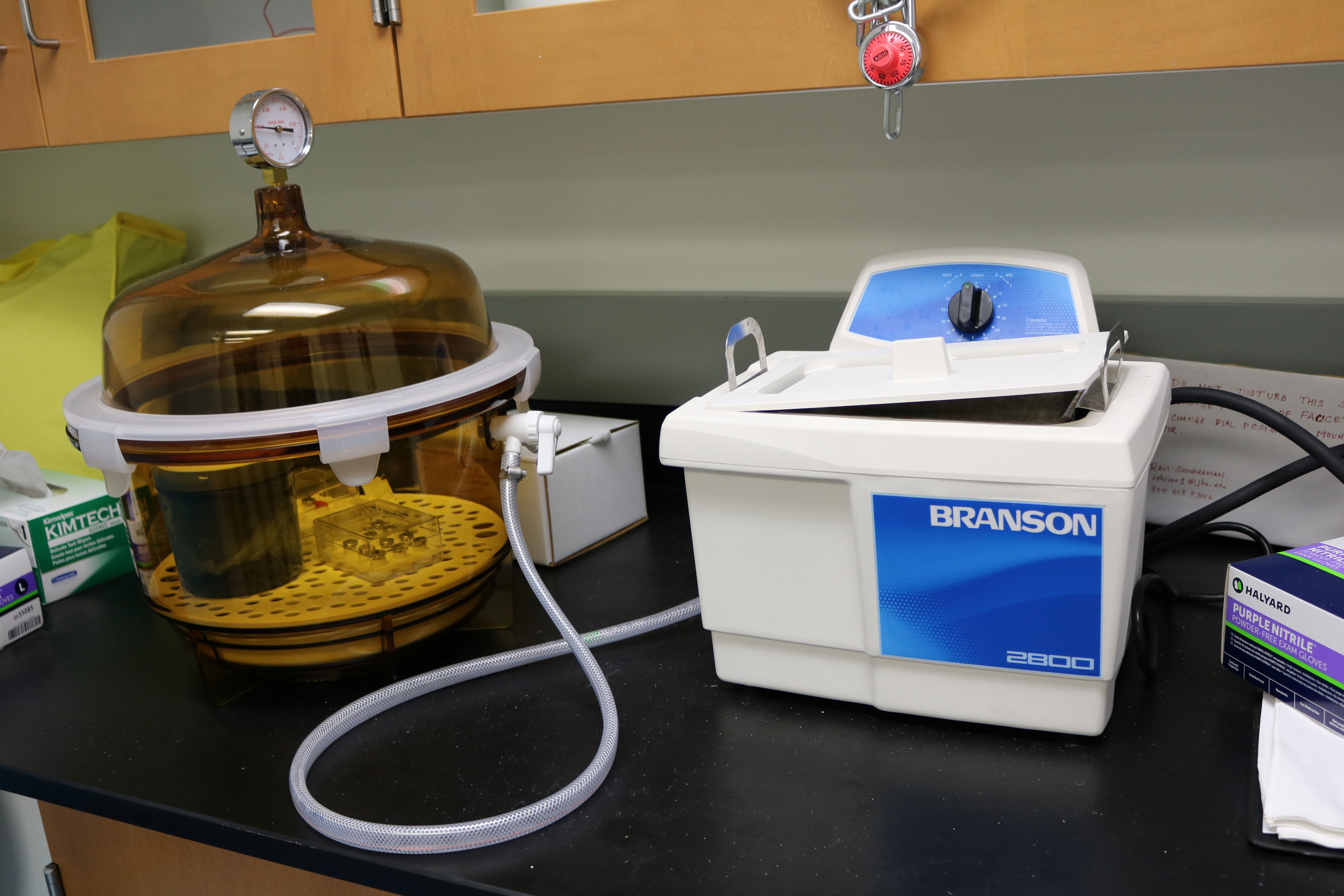

| Specimen Preparation Facility This facility contains several pieces of equipment to prepare specimens for both testing and characterization. Equipment includes low and high speed saws, automated polishing machines, a lapping machine, an electro-polisher and an ion-milling machine.

|

| Shock Tube Test Facility This facility uses a 3-inch shock tube to dynamically load soft materials and tissue specimens. Dynamic pressure measurement and high-speed 3D digital image correlation capture material response. This facility is Biosafety level 2 and includes a biosafety cabinet for preparation of tissue samples. |

| Drop Weight Test Facility The high energy drop tower delivers impacts between 1 and 30 m/s with specified energy up to 1800 Joules to both solid materials and tissue specimens. An environmental chamber allows control of ambient temperature, and tests can be visualized with high-speed imaging.

|

| Maryland Advanced Research Computing Cluster (MARCC) | The major computational resources available are through the Maryland Advanced Research Computing Cluster (MARCC). MARCC construction was funded by the State of Maryland, and it is jointly managed by Johns Hopkins University and the University of Maryland. Operating expenses and systems support staff are covered through indirect costs, and faculty are expected to add hardware to the cluster for use on specific research grants. The current Bluecrab cluster comprises over 23,000 cores and 144 GPU’s for accelerated computing, with combined peak performance of over 1.5 Petaflops. A Lustre parallel file system provides over 2 Petabytes of disk storage, and 56 Gb/s Infiniband connectivity is used for all parallel applications messaging and I/O. A second ZFS file system with approximately 12 Petabytes capacity is available for storing and processing big data. MARCC’s data center has a total of 96 racks to house servers, of which 30 are available to add high density compute nodes and storage. Most of the time at MARCC is allocated by the Deans, but MEDE funds were used to purchase a set of nodes. A corresponding number of CPU hours is available by application to the HEMI Computing Committee. Preference has been given to MEDE projects. |

| Homewood High Performance Cluster (HHPC) | HEMI has a share of the Homewood High Performance Cluster. HEMI users can be added to use this account. This cluster is slated for closure around January 2020. |

| Data Storage | HEMI has 80 TB of storage space available on our dataservers, with an additional 12 TB of back-up storage for data exchange servers and backups. We have specialized software and tools for the archival, curation and search of big data, as well as a variety of data analytics suites. In broad terms, we bring the computational analysis to the data when big data is involved. |

| Visualization servers | The HEMI labs have two Dell quad-core Linux-based desktop servers for visualization of data intensive images. These use NVIDIA graphics cards. |

| Software packages and development | Software packages available in the HEMI lab include: Visit, Uintah, Abaqus, LS-Dyna, Paraview, Atomeye, Gimp, Emacs, LaTeX, Microsoft Visual C++ and associated Visual Studio Tools. We perform software development in a Gitlab environment, teaching students about version control and co-development. |

HEMI possesses multiple other resources:

- Meeting Rooms – HEMI owns three rooms in Malone Hall that can be reserved for special meetings and events.

- MTS Universal Test machine

- High-speed photography equipment – HEMI has access to multiple high-speed cameras that cover a range of framing rates, resolutions, and wavelengths. These include:

- One Specialised Imaging Kirana camera – 924 x 768 x 30 um pixels at 10 bit depth, framing speeds up to 2 million full resolution frames per second, 180 frames per capture, and shutter speeds down to 250 nanoseconds

- One Shimadzu HPV-X2 camera – Can capture images at up to 5 million frames per second, with 400 x 250 x 32 um pixels, 128 frames per capture, and 200 ns exposures.

- One Hadland Ultra-8 framing camera – Can obtain 100 million frames per second, capturing 8 frames with exposure times down to 20 ns, and

- Two Photron SA-5s – Capable of being used for dynamic stereo DIC, with 1 Megapixel resolution at 7,500 frames per second and 256 x 256 pixels at 87,500 frames per second.

- Light source equipment – HEMI has access to a variety of high-intensity light sources for high-speed photography, including a 400 W Specialised Imaging pulsed laser diode (SI-LUX640) of 640 nm wavelength, several high-intensity Photogenix flash lamps, and high-intensity coaxial LED sources.

- Whiting School of Engineering Manufacturing facilities

- Nanoindenter mechanical testing system