Using the crystal plasticity approach to parse the effects of alloying and aging on the mechanical behavior of wrought Mg alloys – on the road to Mg ICME

S.R. Agnew, J.J. Bhattacharyya, and F. Wang

Having a predictive model for the collective effects of solid solution alloying, precipitation (of both shearable and non-shearable precipitates), and grain size on the mechanical properties of a given alloy is one of the “holy grails” of mechanical metallurgy. Furthermore, it is a requirement for those who wish to design alloys, either from the top down or the bottom up. For alloys with a cubic crystal structure, this is challenging. In the case of hexagonal close packed Mg alloys, this challenge is even greater, given the more challenging problem of polucrystal homogenization and the multiple deformation mechanisms that operate at the grain level. Research over the past decade has highlighted the significant impact precipitate shape and orientation could potentially have on the strength of Mg alloys. This lecture will show, with examples taken from observations of a rare earth containing Mg alloy, that the crystal plasticity approach has enabled the level of our predictive capability to rapidly approach the level, which exists in other more mature alloys systems.

Development of heat-treatable wrought magnesium alloys with excellent room temperature formability

T.T. Sasaki1, T. Nakata2, B. C. Suh1, M. Z. Bian1, S. Kamado2, and K. Hono1

1National Institute for Materials Science, Tsukuba 305-0047, Japan

2Nagaoka University of Technology, Nagaoka, Japan

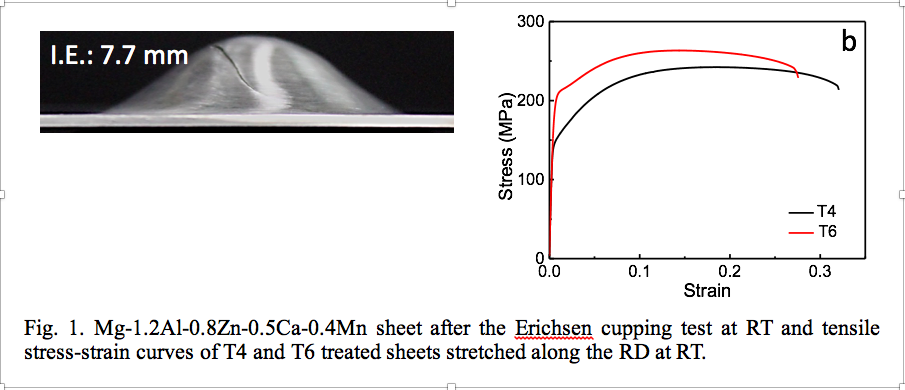

Since age-hardening responses of magnesium alloys without rare earth elements are poor, precipitation hardening has not been used in conventional wrought magnesium alloys. However, optimizations of alloy compositions often lead to the formation of metastable nano-sized precipitates during artificial aging, which substantially enhances the yield strength. In general, the room temperature formability of magnesium alloy sheets shows negative correlations with yield strength; hence magnesium alloy sheets with relatively good formability all have low yield strength. In this work, we aimed at developing heat-treatable wrought magnesium alloys that can exhibit good room temperature formability with high yield strength and ductility for potential automotive body applications. Solution treated (T4) alloys in general have low yield strength; hence, they can show good formability if texture is weakened. Using improved age-hardening responses in compositionally tuned magnesium alloys, the yield strength of formed sheets can be enhanced by short-time artificial aging. In this talk, we present examples of age-hardening wrought alloys including Mg-Zn-Al, Mg-Al-Ca and Mg-Sn-Zn-Al systems, all of which use only ubiquitous elements. Among these, Mg-1.3Al-0.3Ca-0.4Mn (wt.%) alloy can be extruded at high die-exit speed of 24 m/min and it can be bake-hardened by the precipitation of Guinier-Preston zones. The peak aged AXM10304 exhibited yield stress of 288 MPa and elongation of 21 %, which are superior to those of 6000 series aluminum alloys. One of the alloys we have developed, Mg-1.2Al-0.8Zn-0.5Ca-0.4Mn (wt.%) alloy, shows excellent room temperature formability with Erichsen value of 7.7 mm and a high yield strength over 200 MPa after T6 treatment. The systematic investigations toward the development of such heat-treatable and formable wrought magnesium alloys will be presented.

Precipitates and Lattice Defects in Mg Alloys

J.F. Nie

Department of Materials Science and Engineering

Monash University, Victoria 3800, Australia

Significant progress has been made in the past 17 years in the understanding of microstructures of magnesium alloys and their impact on mechanical behavior, through the application of advanced experimental techniques and the use of integrated computational materials engineering. However, there are still some controversial views and unresolved issues on the structures of precipitates and the identities of lattice defects in magnesium alloys of technological or commercial significance. This presentation will provide a review of our recent findings in the study of precipitates, stacking faults and dislocations in a group of magnesium alloys using atomic-resolution Z-contrast scanning transmission electron microscopy and first-principles density functional theory.

Observing and Characterizing the Deformation of Mg and Its Alloys at High Strain Rates

Timothy P. Weihs

Abstract: To effectively model and predict the mechanical deformation of magnesium and its alloys at high strain rates one must understand the active deformation mechanisms. To do so we have developed and employed several in situ techniques using x-ray, electron, and optical sources. By performing mini Kolsky bar experiments at the Advanced Photon Source we have identified the evolution of twins in Mg at strain rates approaching 104 s-1, and we have observed twin formation and dislocation slip in tension at similar strain rates using the dynamic TEM at LLNL. Lastly, we have used high-speed optical cameras to quantify twin velocities and characterize twin evolution during rapid loading of Mg single crystals. In addition to these unique observations we have characterized the dynamic strength, the spall strength, and the spall behavior of pure Mg and AZ31B over a range of strain rates and loading geometries. We have also characterized Mg single crystal deformation under shock loading. The resulting properties and stress-strain curves are compared to model predictions that leverage detailed inputs of the as-fabricated microstructures. This combination of experimental results and model predictions show improvements in our ability to both understand and predict the dynamic behavior of Mg-based materials, and they will enable us to design Mg alloys with improved dynamic performance.